DIY Repair of Damaged Power Tool Cords and Plugs: Safety Tips

Power tools are essential for professionals and hobbyists alike, but even the most durable tools aren’t immune to damage. One of the most common issues involves cords and plugs—two components that are vital to the functionality of your tools. A frayed cord or a damaged plug might seem like a minor problem, but it can lead to electrical hazards, such as short circuits, fires, or even severe injuries.

If you’re considering a DIY repair of damaged power tool cords and plugs, it’s important to prioritize safety above all else. By understanding the repair process and following proven safety practices, you can save money, reduce downtime, and protect yourself from potential harm. For additional information on quality tools and accessories, don’t forget to explore Bestusatools, a comprehensive resource for tool enthusiasts.

Understanding the Risks of Using Damaged Cords and Plugs

Before diving into repair techniques, it’s critical to understand why damaged cords and plugs are a serious issue. According to the Electrical Safety Foundation International (ESFI), electrical malfunctions cause over 51,000 home fires annually in the U.S., with damaged cords being a leading contributor. Here’s why repairing or replacing damaged cords and plugs promptly is crucial:

- Fire Hazards: Exposed wires can easily ignite nearby materials.

- Electrical Shocks: Damaged insulation increases the risk of accidental contact with live wires, leading to shocks.

- Tool Malfunctions: A faulty cord or plug can disrupt the flow of electricity, causing the tool to function unpredictably or not at all.

Repairing these components isn’t just about keeping your tools operational—it’s about keeping yourself and others safe from potential hazards. For an effective guide on resolving this issue quickly, check out this resource on unclog toilet with plunger. With step-by-step instructions, you’ll have your plumbing back in order in no time.

Assessing the Extent of Damage to Cords and Plugs

Before attempting a DIY repair, take the time to thoroughly inspect the damage. Use the following checklist to evaluate whether the cord or plug is repairable or if replacement is necessary:

- Minor Cuts or Abrasions: Small nicks in the insulation can often be patched with electrical tape or heat-shrink tubing.

- Exposed Wires: If the outer insulation is completely worn, exposing live wires, you’ll need to take extra precautions during the repair process.

- Damaged Plug: Broken prongs or loose connections in the plug usually require a complete replacement of the plug itself.

- Severe Internal Damage: If the cord is cracked, burned, or has sustained water damage, replacing the entire cord is often safer.

Essential Tools and Materials for Repair

To successfully repair damaged power tool cords and plugs, you’ll need the right tools and materials.

Having these items on hand will streamline the process:

- Wire Strippers: For cutting and stripping insulation from wires.

- Electrical Tape: To insulate repaired sections of the cord.

- Heat-Shrink Tubing: Provides a durable, waterproof seal over repaired wires.

- Replacement Plug: A high-quality, grounded plug for replacing broken ones.

- Multimeter: To test for continuity and ensure repairs are safe and functional.

- Utility Knife: For precise cutting of damaged insulation.

Step-by-Step Guide to Repairing Power Tool Cords

Step 1: Safety First

Always unplug the tool before starting any repairs. Wear insulated gloves to protect yourself from electrical shock, and work in a well-lit, dry area.

Step 2: Locate and Inspect the Damage

Carefully examine the cord for cuts, frays, or exposed wires. If the plug is damaged, inspect the prongs and internal wiring.

Step 3: Repair Minor Cord Damage

For small nicks, wrap the affected area with electrical tape. For more extensive damage, slide heat-shrink tubing over the damaged section, use a heat gun to shrink it into place, and ensure the seal is tight.

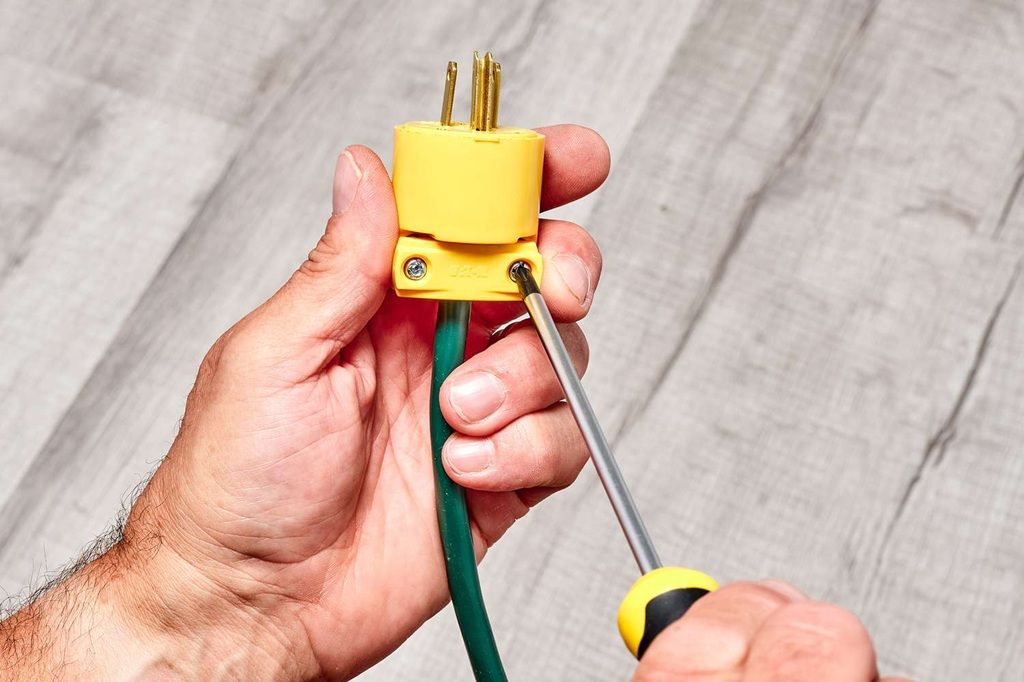

Step 4: Replace the Plug

If the plug is broken, cut it off using wire cutters. Strip the insulation from the end of the cord to expose the wires, then connect them to a new replacement plug. Match the wire colors to the correct terminals (green for ground, black for hot, and white for neutral). Tighten the screws securely.

Step 5: Test the Repair

Use a multimeter to test for continuity and ensure there are no loose connections. Once confirmed, plug the tool into an outlet and turn it on to verify functionality.

Related: DIY Car Projects

Additional Tips for Maintaining Power Tool Cords

Preventing damage is always better than repairing it.

Follow these maintenance tips to keep your cords and plugs in great condition:

- Store cords properly by coiling them loosely. Avoid tight loops that can cause kinks.

- Keep cords away from sharp objects, high-traffic areas, and water.

- Use a cord protector to minimize wear at stress points, such as where the cord enters the tool.

- Regularly inspect your tools for signs of wear or damage.

Why Professional Advice Matters

While DIY repairs can save time and money, there are instances where consulting a professional is the safest option. If you’re unsure about the extent of the damage or lack the proper tools, it’s better to seek expert help. Doing so can prevent costly mistakes and ensure your tools remain safe to use.

FAQs

What type of tape should I use for repairing minor cord damage?

Use high-quality electrical tape designed for insulating wires. Avoid using duct tape or other non-electrical tape.

Can I repair a two-prong plug with a three-prong replacement?

It’s possible but not recommended. For safety and grounding purposes, match the replacement plug type to the original plug.

How do I know if a cord is beyond repair?

If the cord has extensive internal damage, is burned, or shows signs of water exposure, it’s best to replace it entirely.

Related: How to use drain rods

Is it safe to use repaired cords for outdoor power tools?

Yes, as long as the repairs are done correctly using weather-resistant materials, such as heat-shrink tubing rated for outdoor use.

How often should I inspect my power tool cords?

Inspect cords before each use, especially if the tools are used frequently or in harsh environments.

Conclusion

Repairing damaged power tool cords and plugs can be a straightforward and rewarding process when done safely and correctly. By following the steps outlined in this guide and prioritizing safety, you’ll not only extend the life of your tools but also prevent potential hazards. Remember, proper maintenance and regular inspections are key to minimizing damage in the first place. Whether you’re a seasoned DIYer or a novice, this guide provides the knowledge and confidence to handle repairs like a professional.