The Art and Science of Industrial Powder Mixing: Practical Approaches and Modern Solutions

Why Industrial Mixing Matters in Modern Manufacturing

In today’s manufacturing landscape, the effective blending of powders plays a crucial role in driving product quality, safety, and efficiency. Industries ranging from food and pharmaceuticals to chemicals and construction depend on consistent blends for everything from taste and texture to efficacy and regulatory compliance. A single batch inconsistency can impact not only the bottom line but also consumer trust and health outcomes. As demands for quality and throughput increase, so too does the need for technologies and systems that ensure uniform and repeatable powder mixtures.

The equipment chosen for mixing is paramount, as it can significantly affect the final product. Among the various options available, the ribbon mixer is frequently cited for its versatility and ability to provide thorough, homogeneous blends even with challenging powder types. These blenders are widely utilized in sectors where precision and batch consistency are fundamental requirements.

Key Types of Powder Mixers Used Today

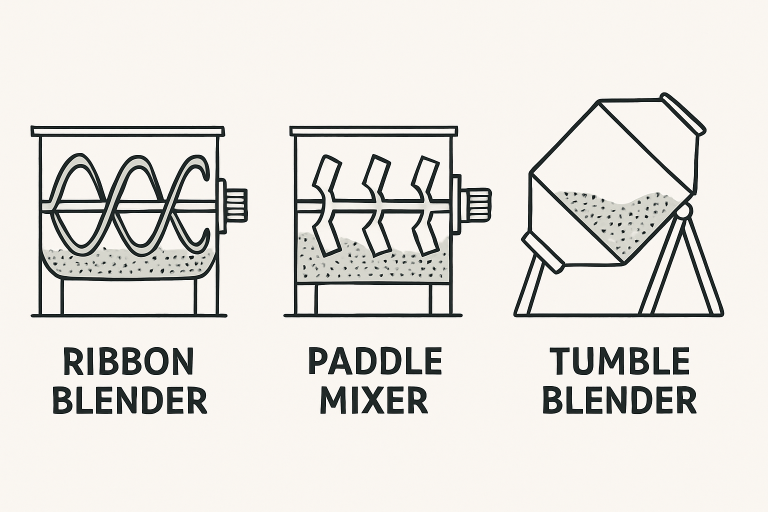

Modern production facilities leverage a variety of powder mixer designs to accommodate diverse material properties, batch sizes, and processing requirements. Ribbon blenders, paddle mixers, and tumble blenders are among the most commonly used industrial mixers. According to a Processing Magazine article on the comparison between ribbon and tumble blenders, the choice of mixer has a significant impact on efficiency, product uniformity, and material integrity.

The Ribbon Mixer, featuring helical agitators in a horizontal configuration, excels at blending powders of varying densities and particle sizes. This design is ideal for bulk processing in the food, chemical, and pharmaceutical industries, where high-efficiency mixing is essential.

Paddle Mixers use flat blades to gently agitate powders, offering effective mixing for fragile or heat-sensitive materials while maintaining product integrity.

Tumble Blenders rely on slow rotational motion to achieve uniformity with minimal shear, making them suitable for delicate powders or mixtures prone to degradation.

Each mixer type offers distinct advantages, and selecting the right design is crucial for matching the product characteristics and production line requirements. By aligning mixer choice with material properties and operational goals.

The Science Behind Effective Powder Mixing

At its core, industrial powder mixing is governed by principles of particle physics and material science. Factors such as particle size distribution, flowability, cohesiveness, and moisture content directly influence how powders interact and disperse. Mixer geometry, impeller speed, and fill volume further impact blend uniformity. A scientific approach to mixing, including real-time data collection and process modeling, can dramatically reduce variability and waste.

Research published highlights that optimal mixing strategies—those tailored to specific powder properties and mixer mechanics—are crucial for ensuring consistent product performance. This is especially vital in pharmaceuticals, where dose uniformity must meet strict regulatory standards.

Best Practices for Achieving Uniform Blends

- Pre-screen powders to remove agglomerates or contaminants before mixing

- Control ambient humidity and temperature to prevent caking and moisture-related issues

- Select the mixer best suited to your specific materials and processing volume

- Implement in-process sample testing and blend analysis to verify homogeneity

- Thoroughly clean equipment between production runs to prevent cross-batch contamination

By rigorously following these practices, industries can minimize rework, reduce product variability, and strengthen compliance with safety and quality regulations. Adopting these measures also contributes to improved throughput and decreased operational costs.

Innovative Technologies and Trends

The digital transformation sweeping through manufacturing is reshaping powder mixing operations. Advanced control systems equipped with smart sensors and connectivity features enable real-time monitoring of blend homogeneity, temperature, and mixer load. Artificial intelligence algorithms can dynamically adjust mixer parameters based on feedback, thereby maximizing batch consistency and minimizing resource utilization. One emerging trend is the adoption of continuous mixing systems, which replace traditional batch processes to significantly cut downtime and deliver consistent results at scale.

Looking Ahead: The Future of Industrial Powder Mixing

The coming years will see a pronounced shift toward more innovative, more sustainable mixing technologies. Integrated analytics platforms, modular mixer designs, and energy-efficient motors are already reshaping the landscape. As environmental stewardship and regulatory scrutiny grow, manufacturers will prioritize eco-friendly mixer construction and operation. Rapid-change components and user-friendly automated systems will empower operators while driving continuous productivity gains.

To keep pace with these advancements, organizations should foster a culture of ongoing education, process experimentation, and early adoption of new technologies. By doing so, they will ensure the highest levels of efficiency, quality, and safety in their powder blending processes as the industry continues to evolve.

Conclusion: The Critical Role of Industrial Powder Mixing

Adequate powder mixing remains a cornerstone of modern manufacturing, directly influencing product quality, safety, and operational efficiency. From selecting the right mixer type to applying scientific principles and best practices, every decision in the mixing process contributes to achieving consistent and reliable outcomes. As technology advances, integrating innovative systems, automation, and sustainable designs will further enhance batch uniformity, reduce waste, and improve productivity. By embracing these innovations and maintaining rigorous process standards, manufacturers can ensure their products meet both regulatory requirements and customer expectations, securing a competitive edge in an increasingly demanding market.