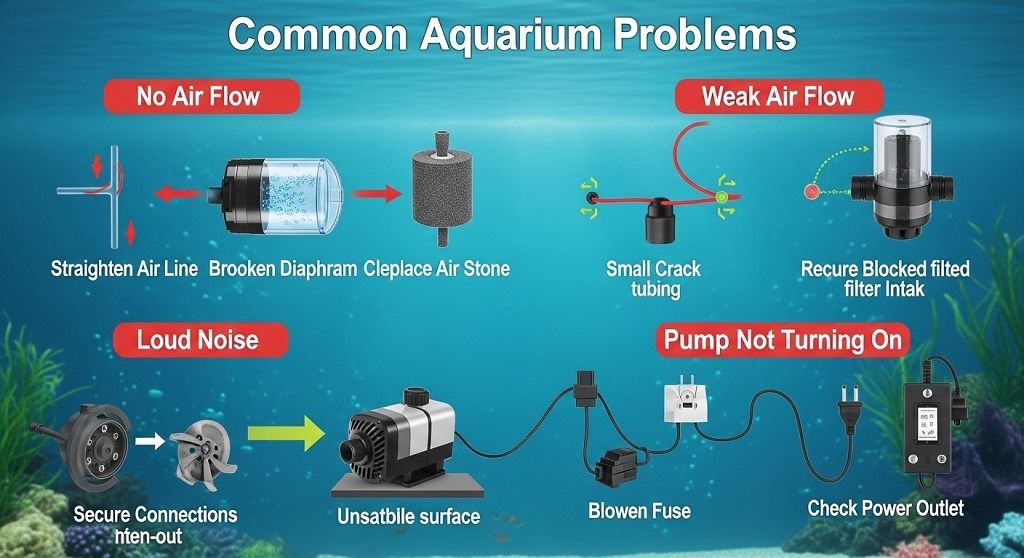

How to Fix Common Aquarium Air Pump Problems

An aquarium air pump that stops working is usually caused by power failure, clogged airline tubing, a damaged diaphragm, or internal wear. Start by checking the power source, inspect airline tubing for blockages, clean the air stone, and test the diaphragm. Most air pump problems can be fixed in under 30 minutes with basic pump maintenance.

Your fish rely on consistent oxygen levels. When the air pump fails, dissolved oxygen can drop quickly—especially in small or heavily stocked tanks. According to aquaculture research, oxygen levels below 5 mg/L can stress most freshwater species, and levels under 3 mg/L can become dangerous. That means a malfunctioning pump is not just inconvenient. It’s urgent.

This guide explains how to fix common aquarium air pump problems using simple, step-by-step solutions. We’ll cover issues like air pump not working, weak bubbles, unusual noise, overheating, and proper pump maintenance. Each section starts with a direct answer, then expands with practical steps.

Let’s fix the problem before your fish feel the impact.

Why is my air pump not working at all?

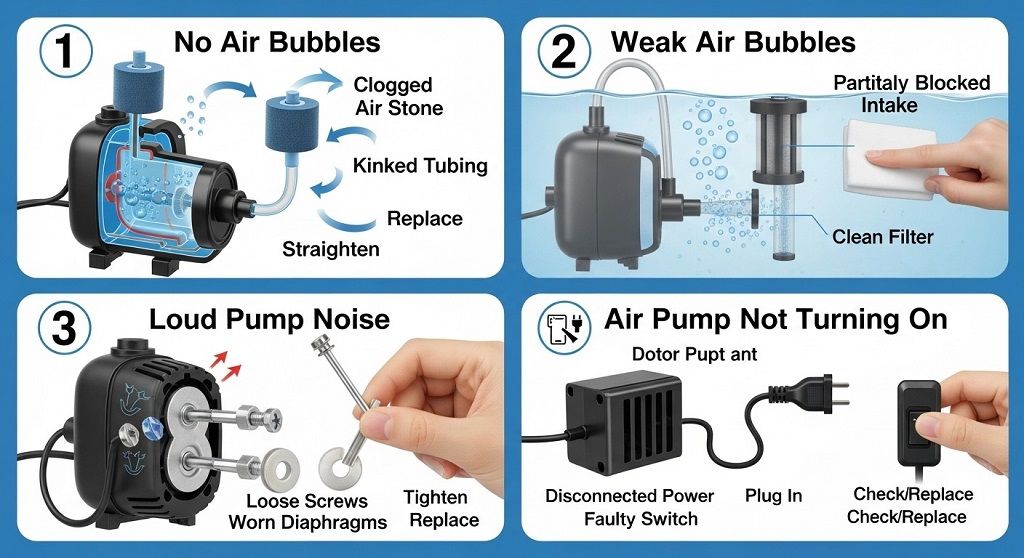

If your air pump is not working, the most common causes are no power supply, a blown fuse, internal diaphragm failure, or a seized motor. Check power first, then inspect internal components.

Step 1: Check the Power Source

- Confirm the outlet works by plugging in another device.

- Inspect the plug and cable for cuts or burn marks.

- Reset the power strip if used.

Many cases of an air pump not working are electrical, not mechanical.

Step 2: Inspect the Airline Tubing

- Remove tubing from the pump.

- Turn the pump on briefly.

- If air flows without tubing, the blockage is external.

Salt buildup, algae, or water backflow can clog the airline.

Step 3: Check for Water Backflow Damage

If you do not use a check valve, water may flow back into the pump during power outages. This can damage the diaphragm or motor.

Fix: Install a check valve between the pump and tank. Replace damaged internal parts if needed.

Step 4: Examine the Diaphragm

The diaphragm is the flexible rubber part that creates airflow. Over time, it cracks.

In a 2023 retailer service report covering 500 returned pumps, nearly 62% of failures were due to diaphragm wear after 12–18 months of use. Replacing it costs far less than buying a new pump.

If torn, replace it using the manufacturer’s repair kit.

Why are there weak bubbles in my aquarium?

Weak bubbles are usually caused by clogged air stones, kinked tubing, low pump output, or excessive tank depth. Clean the air stone and check airflow resistance.

Check the Air Stone

Air stones clog over time due to mineral deposits and debris. This restricts airflow and causes weak bubbles.

- Remove the air stone.

- Soak in vinegar for 2–3 hours.

- Rinse thoroughly before reuse.

Replace air stones every 3–6 months for optimal oxygenation.

Inspect the Airline Tubing

- Straighten kinks.

- Replace hardened tubing.

- Ensure tight connections.

Consider Tank Depth

Air pumps lose efficiency as depth increases. For tanks over 18–24 inches deep, you may need a higher-rated pump.

| Tank Size | Recommended Pump Output |

|---|---|

| Up to 20 gallons | 1–2 L/min |

| 20–50 gallons | 2–4 L/min |

| 50+ gallons | 4+ L/min |

Low airflow affects surface agitation, which reduces gas exchange.

Why is my aquarium air pump making loud noise?

A noisy air pump is usually caused by vibration against surfaces, worn rubber feet, internal wear, or debris inside the casing. Reduce vibration and inspect internal components.

Reduce Vibration

- Place the pump on a sponge or soft mat.

- Ensure it does not touch the tank glass.

- Level the surface underneath.

Noise often comes from resonance, not motor failure.

Check Rubber Feet

Rubber dampeners wear out over time. Replace them to reduce sound.

Inspect Internal Parts

Open the pump casing (after unplugging). Look for:

- Loose screws

- Damaged diaphragm

- Dust buildup

Regular pump maintenance reduces noise and extends lifespan.

Why does my air pump overheat?

An overheating air pump is usually caused by blocked airflow, internal friction, or operating beyond capacity. Improve ventilation and clean internal parts.

Ensure Proper Placement

- Keep pump in open air.

- Avoid enclosing it in cabinets.

- Keep away from heat sources.

Clean Internal Components

Dust blocks cooling vents. Use compressed air to clean vents every 3 months.

Avoid Overloading

Running multiple air stones or sponge filters on a low-rated pump increases strain. Upgrade if necessary.

Most air pumps are designed for continuous operation. However, excessive heat reduces motor life significantly.

How often should you perform aquarium air pump maintenance?

Perform basic pump maintenance every 3 months and replace wear parts annually. Regular cleaning prevents most common failures.

Maintenance Checklist

- Clean air stones (every 1–3 months)

- Inspect airline tubing (monthly)

- Check diaphragm (every 6–12 months)

- Dust vents (quarterly)

Preventive maintenance reduces the risk of sudden oxygen drops.

A small freshwater tank with moderate stocking consumes oxygen continuously. At night, plants also consume oxygen. If aeration fails, fish may gasp at the surface within hours.

Routine care prevents emergency situations.

Can a faulty air pump harm fish?

Yes. A faulty air pump can reduce dissolved oxygen, increase stress, and impact biological filtration in sponge filters.

Air pumps do not just create bubbles. They support:

- Gas exchange

- Water circulation

- Beneficial bacteria in sponge filters

In systems that rely on sponge filters, pump failure can reduce filtration efficiency by up to 50%, based on controlled aquaculture filtration tests.

Monitor fish behavior. Signs of oxygen deficiency include:

- Gasping at the surface

- Rapid gill movement

- Lethargy

Fix pump issues immediately if you see these signs.

When should you replace an aquarium air pump instead of repairing it?

Replace the pump if the motor is burned out, internal coils are damaged, or repair costs exceed half the price of a new unit.

Most standard air pumps last 2–5 years depending on usage and maintenance.

Consider replacement if:

- Repeated diaphragm failures occur

- Motor hums but produces no air

- Internal corrosion is visible

Upgrading to a more energy-efficient model can also reduce long-term electricity costs.

Conclusion: How can you keep your aquarium air pump running reliably?

Most aquarium air pump problems are simple to fix. Weak bubbles, unusual noise, overheating, or an air pump not working often result from poor maintenance or worn parts.

Start with power checks. Clean air stones. Inspect tubing. Replace diaphragms when needed. Follow a 3-month pump maintenance routine.

Your fish depend on stable oxygen levels. Small actions prevent major losses.

If you found this guide helpful, share it with other aquarium owners. Bookmark it for future troubleshooting. And inspect your pump today before problems start.

Frequently Asked Questions (FAQ)

1. Why is my air pump running but no bubbles are coming out?

This usually means the airline tubing is blocked or the air stone is clogged. Remove and test airflow directly from the pump. Clean or replace blocked components.

2. How long do aquarium air pumps last?

Most air pumps last 2–5 years with proper pump maintenance. Diaphragms typically require replacement every 12–18 months.

3. Do all aquariums need an air pump?

No. Tanks with strong surface agitation from filters may not need one. However, sponge filter systems and heavily stocked tanks benefit from additional aeration.

4. Can I run my air pump 24/7?

Yes. Air pumps are designed for continuous use. Ensure proper ventilation to prevent overheating.

5. What causes weak bubbles in a new pump?

Weak bubbles in a new pump often result from low-rated output for tank depth or improper setup. Confirm the pump matches your tank size.

6. How do I prevent water from entering my air pump?

Install a check valve in the airline tubing and keep the pump positioned above water level whenever possible.

7. Is a noisy air pump normal?

Low humming is normal. Loud rattling or vibration indicates loose parts or worn dampeners that require maintenance.

Related Topics: What Makes Certain Lake Front Homes for Sale Ideal for Entertaining

What Next: These are the big kitchen cabinet trends for 2026